Fiberglass Nonwoven Asphalt Overlay | Premium Pavement Reinforcement Solution

Product Overview

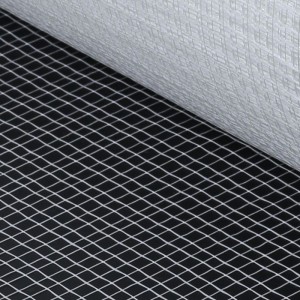

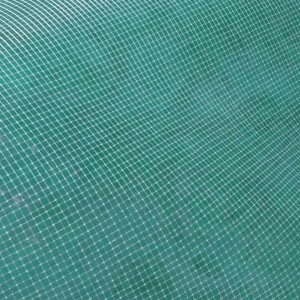

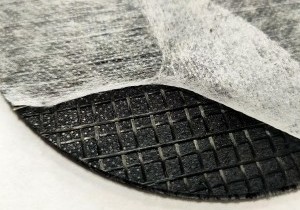

Our Fiberglass Nonwoven Asphalt Overlay is a high-performance, composite material designed to extend pavement lifespan by reinforcing asphalt surfaces. Combining a durable nonwoven fiberglass mat with a polymer-modified asphalt coating, it delivers superior resistance to cracks, moisture, and heavy traffic. Ideal for highways, municipal roads, and commercial parking lots in the U.S. and Canada.

Key Features & Benefits

1. Exceptional Durability

- Glass fiber reinforcement resists tensile stress, preventing reflective cracks.

- Modified asphalt coating ensures long-term adhesion and flexibility (-30°C to 80°C).

2. All-Climate Performance

- Withstands freeze-thaw cycles (critical for Canada) and UV exposure (southern U.S. regions).

3. Easy Installation

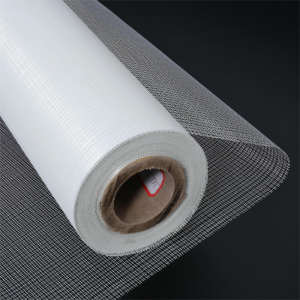

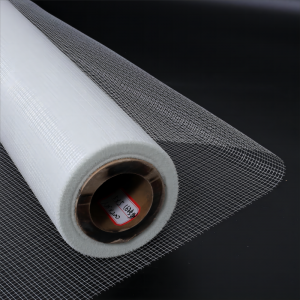

- Prefabricated rolls for fast deployment; compatible with standard asphalt paving equipment.

4. Cost-Effective Maintenance

- Reduces repair frequency by up to 50% compared to traditional overlays.

5. Eco-Friendly

- Contains recycled materials; LEED® contribution potential.

Technical Specifications

| Parameter | Value |

|---|---|

| Material | Fiberglass nonwoven + SBS-modified asphalt |

| Thickness | 2.5–4.0 mm (±0.2 mm) |

| Roll Size | 1m × 25m (Customizable) |

| Tensile Strength | ≥35 kN/m (ASTM D4595) |

| Temperature Range | -30°C to 80°C |

Applications

- Function:

- Seals and reinforces aged asphalt/concrete pavements by bridging existing cracks (up to 5mm wide) and preventing reflective cracking.

- Acts as an interlayer between old and new asphalt layers, extending pavement life by 8–12 years.

- Use Cases:Technical Note: Compatible with infrared thermal repair for seamless integration.

- Urban road resurfacing (e.g., pothole-prone intersections).

- Repairing alligator cracks on highways without full-depth reconstruction.

-

- Function:

- Embedded within asphalt layers to distribute load stress, reducing rutting and fatigue cracking under heavy traffic (e.g., 80+ kN axle loads).

- Enhances tensile strength by 40% compared to non-reinforced asphalt (per ASTM D7460 testing).

- Use Cases:

- Highways: Critical for jointless continuous paving in expansion zones.

- Airport Runways: Withstands jet blast and fuel exposure (FAA-approved grades available).

- Technical Note: Requires hot-mix asphalt (HMA) compaction at 150–160°C for optimal bonding.

- Function:

Function:

Forms a non-permeable barrier against water ingress, preventing corrosion of steel reinforcements in concrete bridge decks.

Resists chloride ion penetration (ASTM C1543 compliance), crucial for coastal regions.

Use Cases:

Bridge Decks: Installed under asphalt wearing courses (e.g., orthotropic steel bridges).

Underground Parking: Blocks rising dampness and oil spills.

Technical Note: Pair with torch-applied modified bitumen for vertical surfaces.

- Function:

- Lighter-grade variants (1.5–2.5mm thickness) provide crack resistance for low-speed, low-load areas.

- UV-stabilized surface resists fading and degradation in driveways.

- Use Cases:Technical Note: DIY-friendly with cold-adhesive backing options.

- Home Driveways: Eliminates seasonal cracking in freeze-thaw climates.

- Community Lanes: Ideal for HOA-maintained roads with 10–50 vehicles/day.