From Composites to High-Performance Textiles: Innovation and Industry Trends in Laid Scrims

In modern materials science, laid scrims serve as a critical reinforcement material combining strength, light weight and process adaptability. They are increasingly applied across sectors including construction, transportation, flooring, textiles and composites, enhancing mechanical performance and enabling manufacturers to create higher-quality, more reliable products.

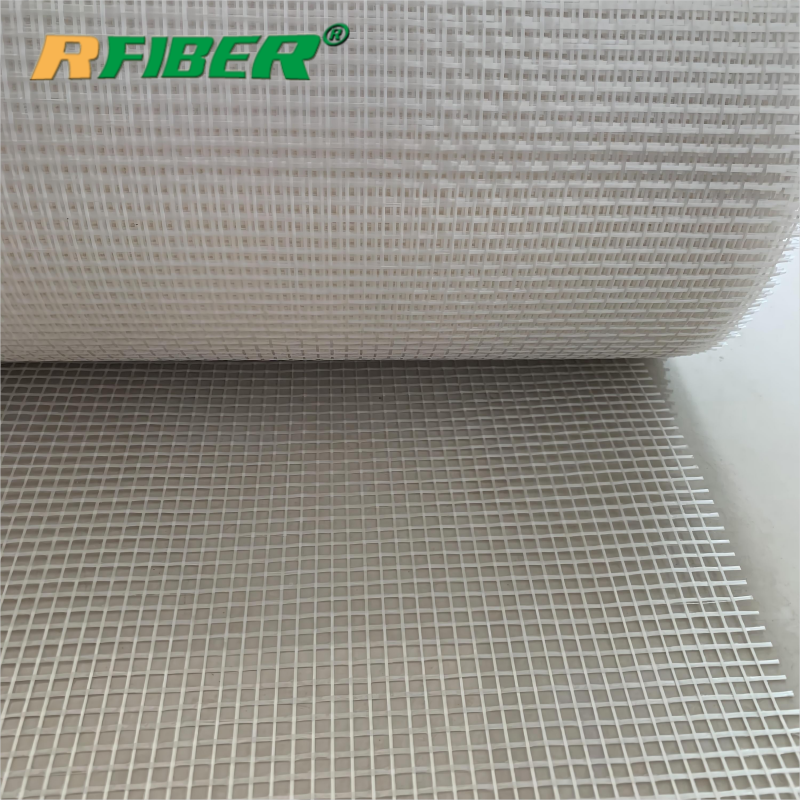

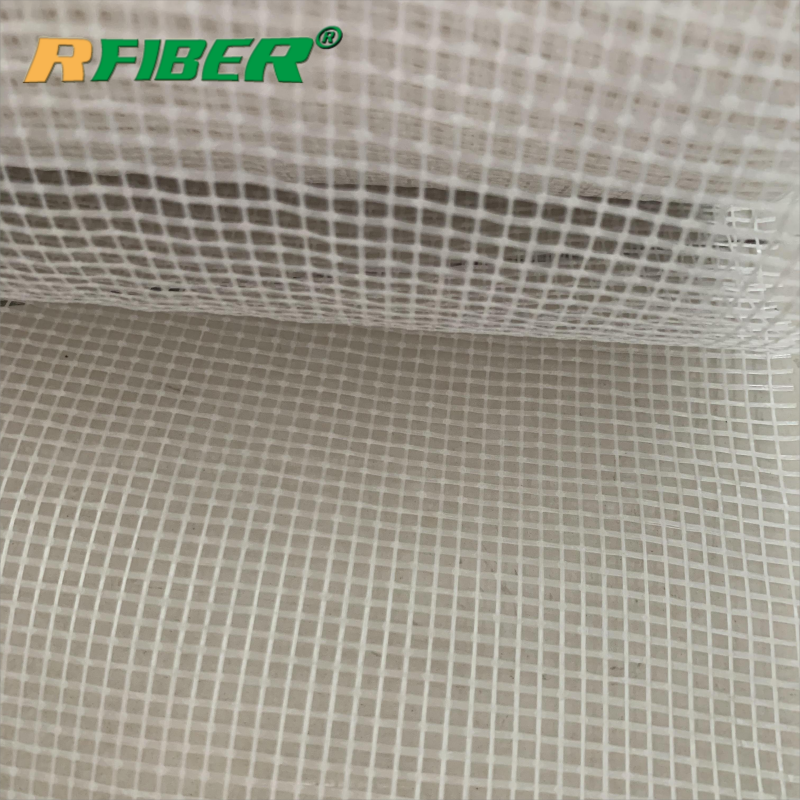

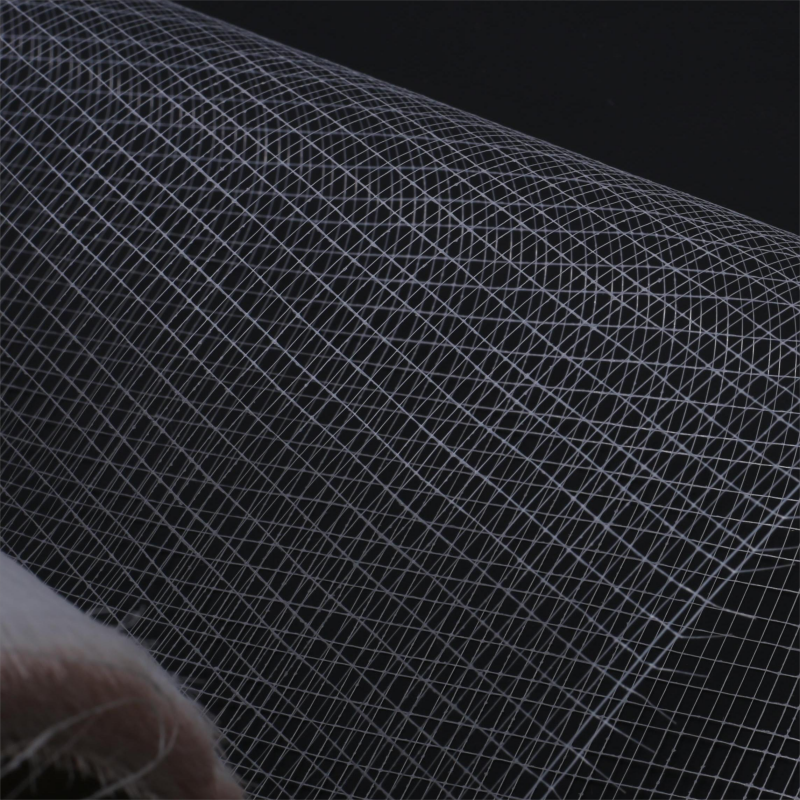

Laid scrims are reinforcement fabrics made by chemically bonding continuous filament yarns into an open mesh structure, capable of bonding with a variety of substrates to improve tensile strength, dimensional stability and durability. Depending on application needs, different yarn materials (e.g., glass fiber, polyester, carbon fiber) and bonding methods (e.g., PVOH, PVC, acrylic) can be selected.

This unique mesh structure ensures lightweight properties while providing strong mechanical performance, making laid scrims indispensable in many high-performance material systems.

RFiber offers a range of laid scrim products designed for diverse uses and manufacturing processes. Below are several key product types and their features:

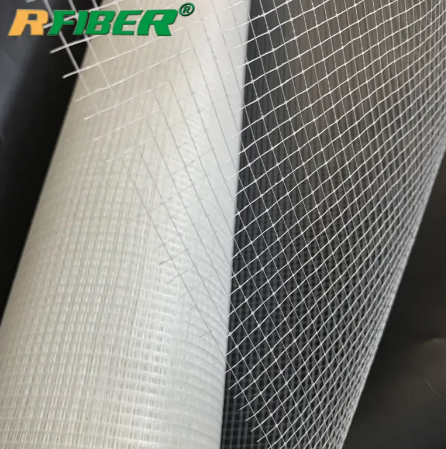

Polyester laid scrims combine cost-efficiency with mechanical performance, featuring open mesh designs that are lightweight yet provide high tensile strength, tear resistance and water resistance. They are commonly used in aluminum foil composites, PVC flooring, non-woven fabric reinforcement and [polyester net fabric laid scrims for reinforced PVC tarpaulin] applications.

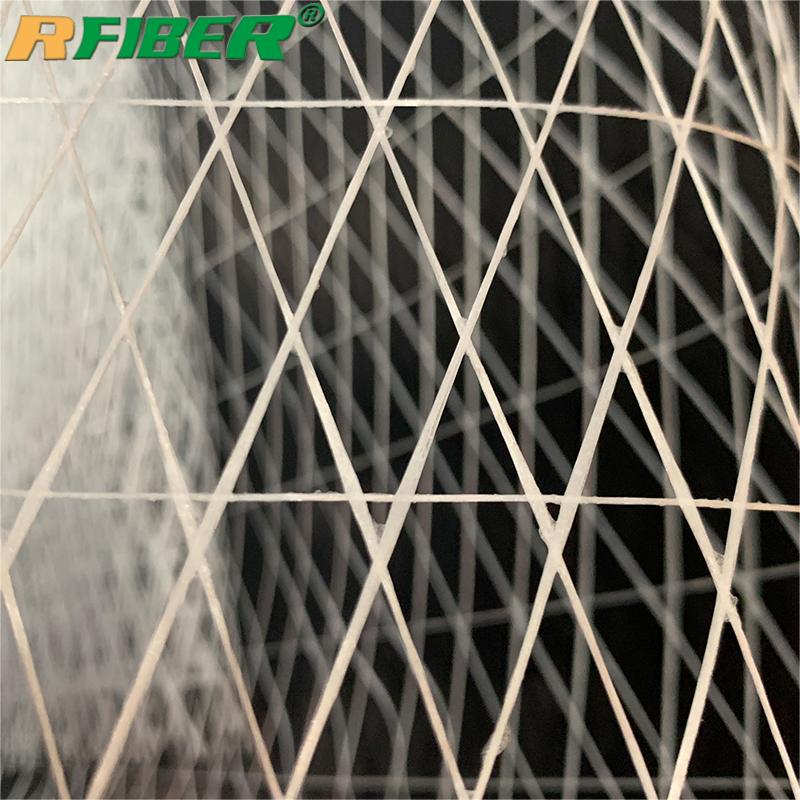

Another innovative product category is triaxial laid scrim, where yarns are oriented at 0°, 90° and ±45°, providing superior performance under multidirectional loads—ideal for structural applications requiring excellent load distribution and impact resistance

For applications requiring easy installation and strong bonding—such as industrial tapes and composite layer reinforcement—hot-melt and coated laid scrim products offer self-adhesive or specialized coating solutions, enabling firm bonding without additional adhesives and improving production efficiency.

For applications requiring easy installation and strong bonding—such as industrial tapes and composite layer reinforcement—hot-melt and coated laid scrim products offer self-adhesive or specialized coating solutions, enabling firm bonding without additional adhesives and improving production efficiency.

In industrial contexts, laid scrims are used to enhance tear resistance and durability of composite parts such as truck tarpaulins, advertising banners, lightweight awnings and other outdoor textile components.

In construction, laid scrims are frequently used to reinforce waterproof membranes, enhance wall systems, and improve load-bearing capacity of flooring materials, helping to mitigate stress concentrations caused by temperature changes.

In industrial contexts, laid scrims are used to enhance tear resistance and durability of composite parts such as truck tarpaulins, advertising banners, lightweight awnings and other outdoor textile components.

Laid scrims are not just efficient reinforcement materials—they are a bridge connecting traditional materials with future high-performance structures. As demands evolve and new applications emerge, their value will continue to expand.

Post time: Feb-04-2026