From Single Reinforcement to Smart Material Systems: New Trends in Laid Scrims Technology

As materials science and engineering advance rapidly, the role of reinforcement materials is undergoing a profound transformation. Traditional reinforcement focused on single performance improvements, while the new generation of solutions demands not only high strength and lightweight properties but also “smart” structural responses, efficient synergy with substrates, and enhanced sustainability.

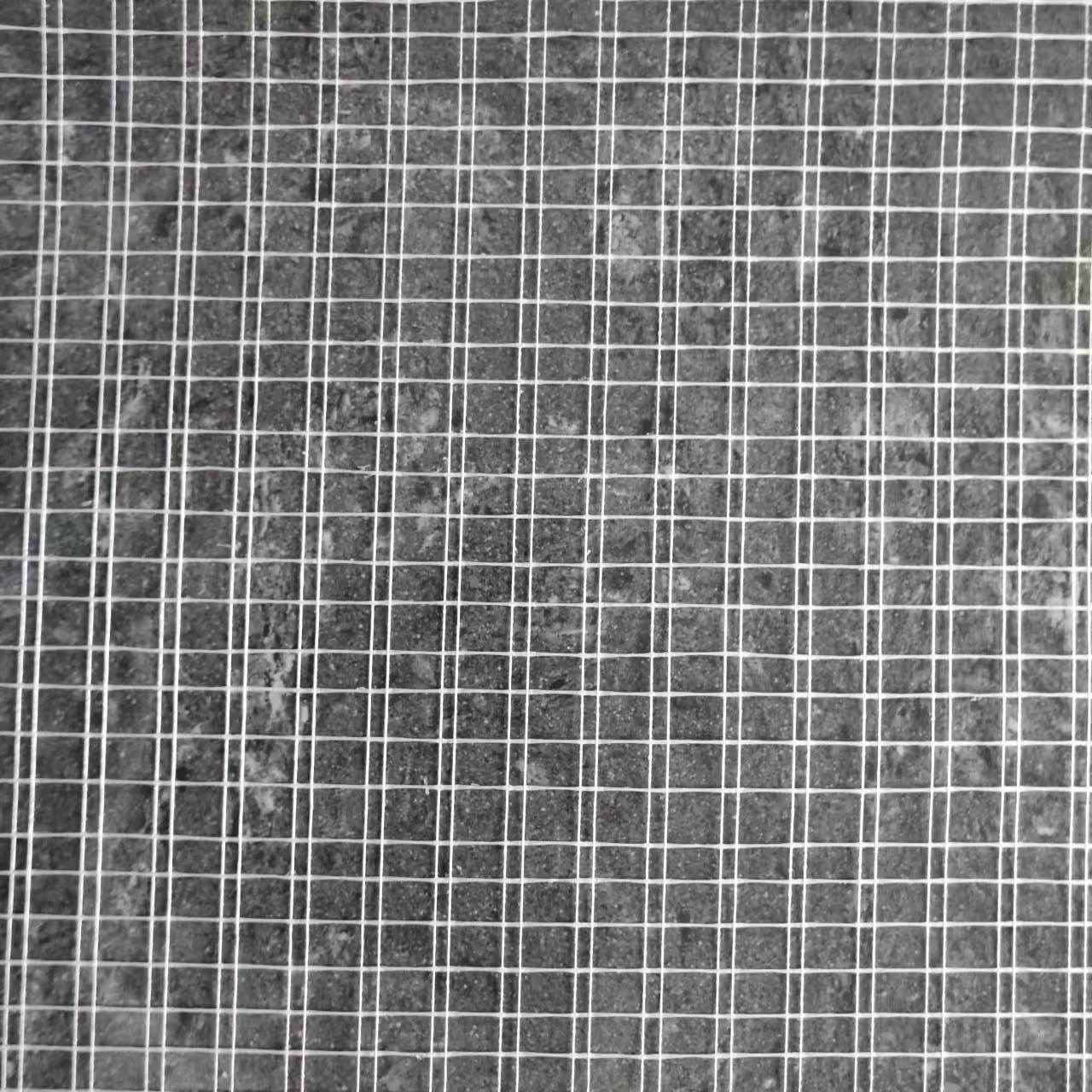

Against this backdrop, the evolution of Laid Scrims technology has become an industry focus. Based on RFIBER’s laid scrim products and their diverse applications, this article explores future technological trends and industry value of laid scrims in advanced material systems.

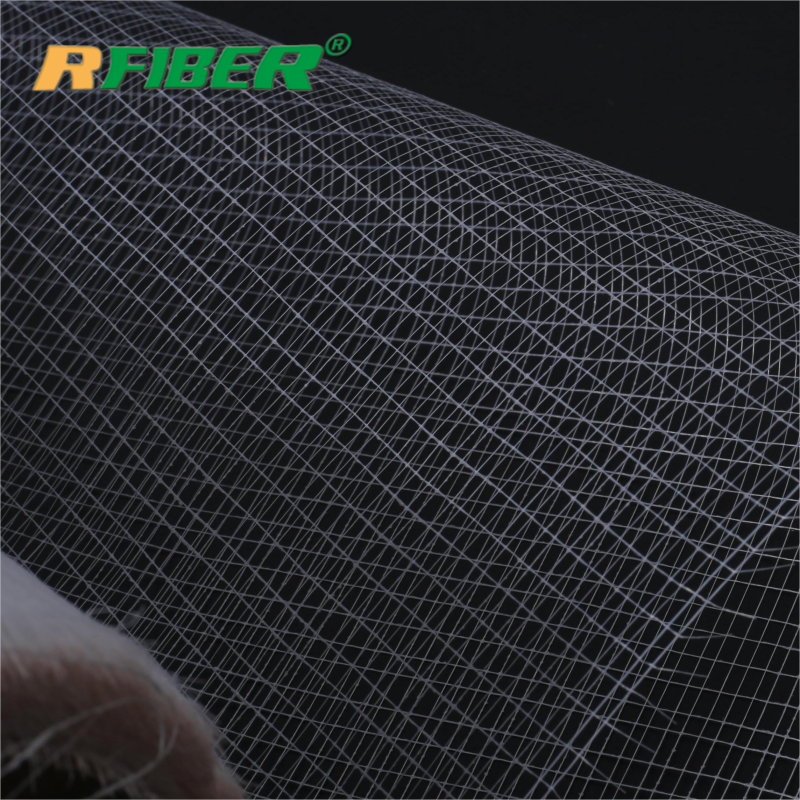

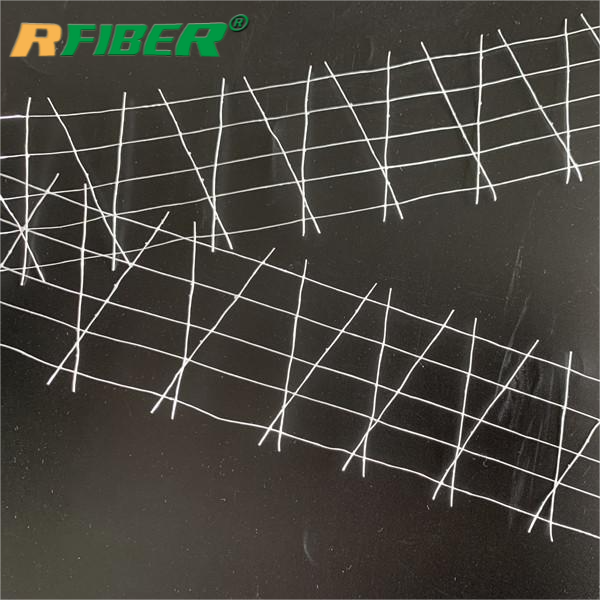

Traditionally, reinforcement materials were mainly designed to improve strength in a single direction, such as tensile or tear strength in composite layers. However, such “unidirectional reinforcement” no longer meets complex load conditions across multiple directions.

New lay-up scrim products integrate more complex yarn orientations and optimized mesh structures, enabling multi-directional stress distribution, thus enhancing overall stability and fatigue resistance of the whole system.

For example, in industrial composites and high-stress protective layers, tri-axial or multi-directional scrims significantly reduce localized stress concentrations, which traditional single-direction reinforcement cannot accomplish.

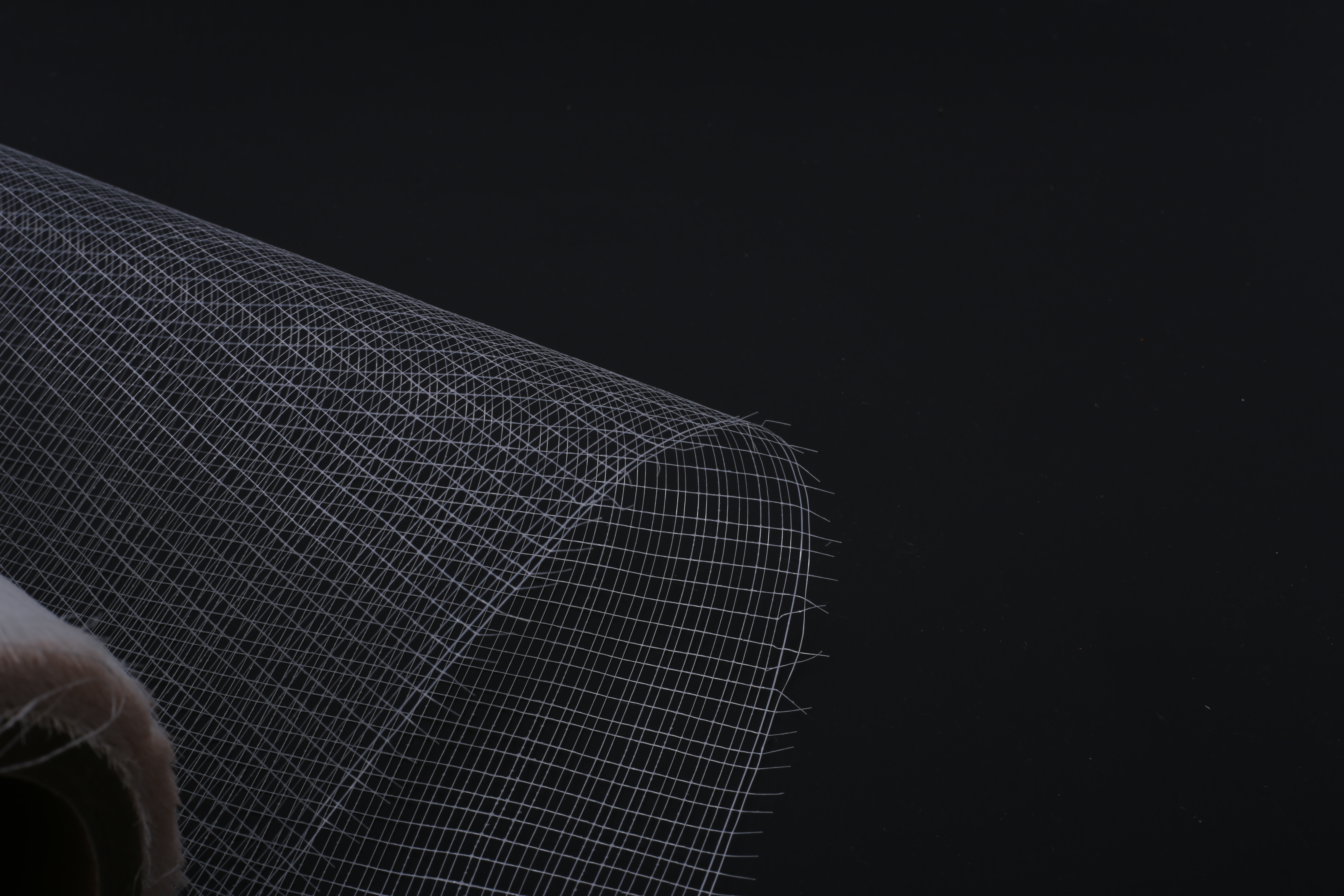

In modern composite systems, reinforcement materials not only provide structural support but also must work synergistically with resins, adhesives, and substrates to achieve optimal mechanical properties and long-term stability.

Advanced laid scrims improve wettability and chemical compatibility with resin systems through optimized surface tension and chemical treatments, resulting in higher interfacial strength in lamination, hot pressing, and bonding processes.

This enhanced synergy drives the broad application of laid scrims in composite manufacturing, industrial laminates, and lightweight automotive components.

Another emerging trend in reinforcement materials is smart response structures. Smart reinforcement materials retain strength and stability while dynamically adapting to changes in temperature, load, or other environmental conditions.

In this realm, combining laid scrims with shape-memory materials, functional fibers, or smart coatings enables future reinforcement systems to have environmental sensing and self-adjustment capabilities—for example, modifying stiffness under temperature shifts or adapting to external stress.

This represents a frontier trend in materials science and signifies deeper advancements in reinforcement technologies.

In lightweight, high-performance composite applications such as aerospace parts, automotive components, and industrial housings, material systems must not only perform well initially but also maintain stability over long service periods.

Laid scrims serve as internal reinforcement layers that enhance fatigue resistance, aging resistance, and impact performance of composite structures, helping extend product life and reduce maintenance costs.

With the global push for green manufacturing, reinforcement materials must also meet sustainability requirements. By adopting low-carbon production processes, recyclable fibers, and minimizing harmful chemical additives, the new generation of laid scrims meets performance demands while aligning with eco-friendly design standards.

This sustainable reinforcement approach enhances environmental friendliness and helps projects meet green construction and low-carbon operation standards.

Modern engineering design emphasizes systemic synergy rather than solely local reinforcement. Laid scrims’ multi-directional stress distribution enables them to act as “synergy bridges” within material systems, distributing forces more evenly and enhancing overall reliability.

This trend drives the industry shift from traditional “material thickening for strength” to “systemic synergy design.”

For end customers, the evolution of laid scrim technologies delivers more than improved product specs. It enhances the entire material system’s reliability and long-term performance:

1.Lower maintenance and rework costs

2.Extended service life

3.Higher structural reliability

4.Better environmental adaptability

This shift from material enhancement to systemic optimization enables customers to gain higher overall value throughout the project or product lifecycle.

As industry standards rise and technologies advance, laid scrim technologies are evolving from basic reinforcement to higher-level development stages that emphasize not only material performance but also synergy with entire systems.

In future material system designs, technological innovation, sustainability, and systemic synergy will be key directions for reinforcement materials.

Choosing the right reinforcement material means choosing a more stable, efficient, and sustainable material system.

Address

info@ruifiber.com

ruifibersales2@ruifiber.com

Phone

Sales: 0086-159-6804-7621

Support: 0086-186-2191-5640

Hours

Monday-Friday: 9am to 6pm

Saturday, Sunday: Closed

WANT TO WORK WITH US?

Post time: Feb-05-2026