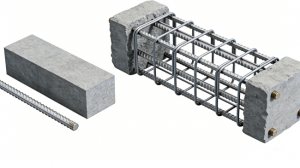

- ➤ The concrete (resin/plastic) is hard but brittle—it can crack under impact.

- ➤ The rebar (reinforcement substrate) is tough and resists pulling forces, but alone, it can’t hold a shape.

- ➤ Combine them: Concrete encases the rebar, creating ultra-strong “reinforced concrete.” The concrete provides shape and hardness, while the rebar handles tension, prevents tearing, and holds everything together.

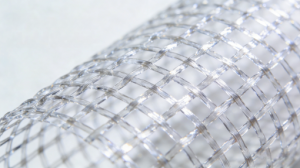

- ① What is it? It’s an invisible internal “skeleton mesh,” often a grid or scrim made of materials like fiberglass or polyester. For example, Fiberglass Laid Scrim is a classic form of this essential engineering fabric, providing a balanced structure for various laminates.

-

① What does it do? It strengthens and supports various otherwise soft or brittle materials. For instance:

-

➤ It makes waterproofing membranes (like roof liners) more resistant to tearing, puncturing, and deformation. Products like Heavy Duty Polyester Scrim are specifically engineered for such demanding applications.

➤ It reinforces flooring, wall coverings, and tarps, making them far more durable. A Standard Polyester Laid Scrim offers an excellent cost-performance ratio for these uses.

➤ It allows automotive plastic components to be lighter without sacrificing strength, where tailored scrim solutions provide the necessary integrity.③Why does it matter? This technology enables products that are simultaneously lightweight, thin, and incredibly strong. Without it, many materials would either be too fragile or need to be impractically thick and heavy. The versatility of specific solutions, like a Customized Reinforcement Scrim, is key to this innovation across industries.

Reinforcement substrates are the "invisible heroes" of composite materials. Like bones and ligaments, they provide crucial support and resilience, allowing for the creation of products that are both robust and lightweight. Discover how our engineered substrates form the foundational strength of your next project.

CONTACT US^^

Post time: Dec-24-2025