Weaving Reliability into Industrial Materials with Precision

In many engineering and industrial applications, attention is often focused on the final product's appearance and surface performance. However, what truly determines its long-term strength, durability, and service life is often the industrial fabric hidden within. It acts like the steel reinforcement in a building, silently bearing the core functions of structural reinforcement, tear resistance, and deformation resistance.

Different weaving structures determine the distinct performance characteristics of the material. We master various advanced processes to meet diverse reinforcement needs.

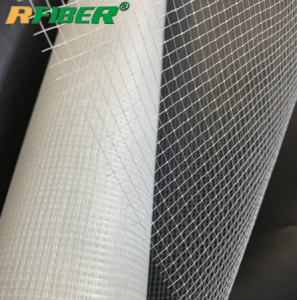

1. Laid Scrim

Yarns are laid in warp and weft directions and bonded, resulting in a stable, lightweight structure with high cost-effectiveness and excellent tensile strength. It is an ideal choice for large-area composite material reinforcement.

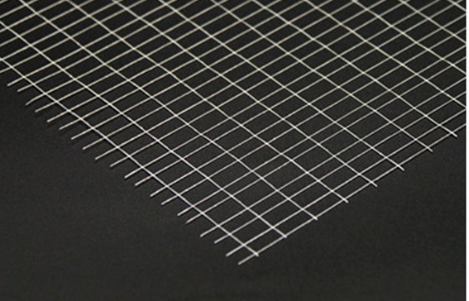

2. Weaving Scrim

Warp and weft yarns are tightly interwoven, creating a robust structure with outstanding abrasion and tear resistance. It is suitable for products with extremely high mechanical strength requirements, such as outdoor tarpaulins and membrane structures.

3. Warping Scrim

The structure is flexible with good elasticity, capable of adapting to complex curved surfaces and bending processes. It is commonly used in composite scenarios requiring good deformation capability.

4. Twisted Scrim

Utilizing a special twisted weaving process, it is suitable for specific reinforcement applications requiring high thickness and high load-bearing capacity.

The base fabric provides the structural support, while the coating endows it with a protective function akin to a "skin". We offer a range of coating solutions:

- 1.SBR Coating

- Offers excellent flexibility and flex-abrasion resistance with high cost-effectiveness. Suitable for outdoor and civilian products.

- 2.PVC Coating

- Provides higher strength, excellent waterproof and anti-mildew properties, and superior weather resistance. Designed for long-term outdoor or harsh environments.

- Through the combination of "Scientific Weaving Structure + Targeted Coating", we ensure each industrial fabric delivers optimal performance in its specific application.

Our industrial fabrics extend far beyond traditional tarpaulins. They have become indispensable reinforcement components in modern material science, widely used in:

- 1.Outdoor & Construction

- Outdoor tarpaulins, shade systems, tensile structures, inflatable products.

- 2.Waterproofing & Sealing

- TPO/PVC polymer waterproof membranes, single-ply roofing systems.

- 3.Industrial & Composite Materials

- Pipe wrapping reinforcement, industrial tape substrates, carpet backing, automotive interior and component reinforcement, aluminum foil composites.

In all these applications, the core value of our fabrics lies in: significantly enhancing the durability and stability of end products, while helping to optimize overall material costs.

We are not just a fabric manufacturer, but a solution partner specializing in laid scrim weaving and lamination technology. We are committed to deeply integrating product technology into application scenarios, providing stable and reliable supply.

1.In PET Composite Materials

Our laid scrim laminated PET films impart exceptional tear resistance and dimensional stability to products like document bags and industrial consumables, supporting multiple reuses and reducing total cost of ownership.

2.In PVC Composite Materials

Through self-developed adhesive systems and process control, our laid scrim laminated PVC films offer excellent anti-wicking properties, effectively preventing moisture penetration. This significantly extends the service life of outdoor tarpaulins and agricultural coverings, and enhances their damage resistance in harsh weather.

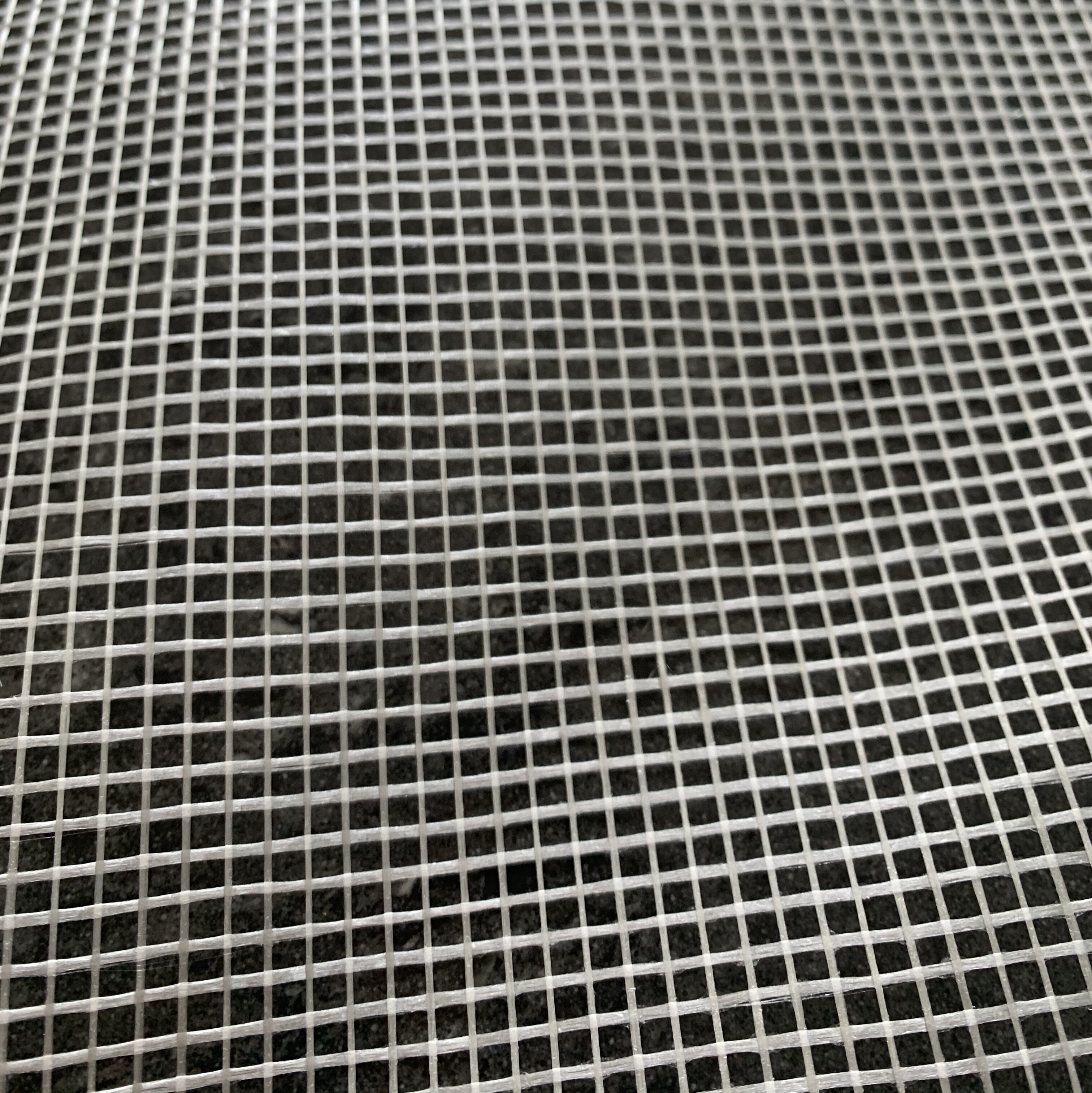

3.High-Strength Polyester Grids

Can be flexibly adapted to single or multi-layer lamination systems, serving broader reinforcement needs.

The value of industrial fabric lies not in its visibility, but in how it silently ensures the long-term reliability of products.

We believe true professionalism is reflected in consistently stable delivery and unwavering quality. From our self-developed adhesive systems and mature weaving and lamination processes, to strict quality control throughout the entire process, we weave "reliability" into every inch of our material.

Choosing RFIBER means choosing a trustworthy long-term partner. We look forward to collaborating with you, using our "invisible" reinforcement technology to jointly build the "visible" market competitiveness of your products.

Post time: Feb-11-2026